VDF SPRINGS

PASSION FORMS PERFORMANCE

More than 400 million parts for more than 500 satisfied customers per year!

Since 1908 products of spring technology, stamping and bending technology as well as chassis technology have been the focus of our work. Our continuous growth accompanied by our high demand on the quality of our products have made the VDF FEDERN Group a major production company in the industry in Europe.

The group includes the companies VDF VOGTLAND Federntechnik, RENZING Federntechnik, KREUTZER Stanz-Biegetechnik, VOGTLAND Autosport and VOGTLAND Holding. The customers of our products are worldwide and spread over a wide range of industries. The automotive supply industry (passenger cars, trucks, motorcycles, rail transport) deliberately occupies a dominant position, accounting for over 55 percent of sales. Other important customer sectors include mechanical and plant engineering, the electrical industry, agricultural machinery manufacturers, the construction supply industry including the fittings industry, the household appliance industry, the furniture industry, measurement and control technology and the capital goods industry, as well as the passenger car aftermarket for sporty automotive accessories.

QUALITY-

ASSURANCE

PASSION FORMS PERFORMANCE

Our goal is to manufacture and sell products, assemblies and services in the field of spring, stamping, bending and chassis technology that meet customer requirements and consolidate the trust of customers or win that of new customers.

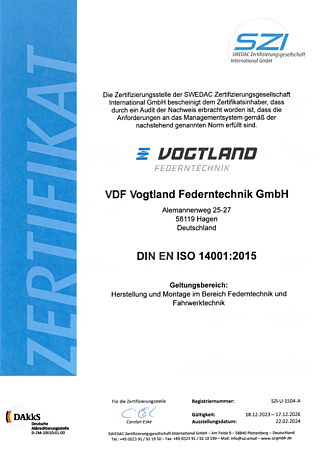

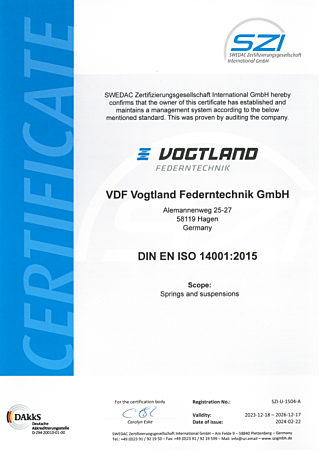

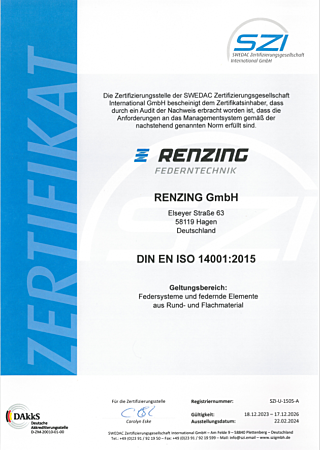

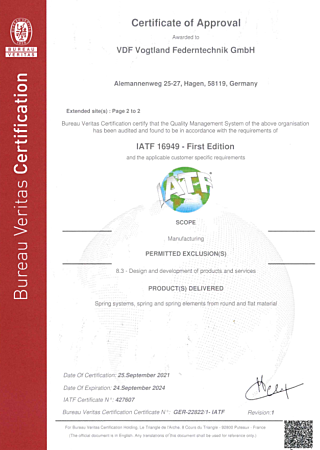

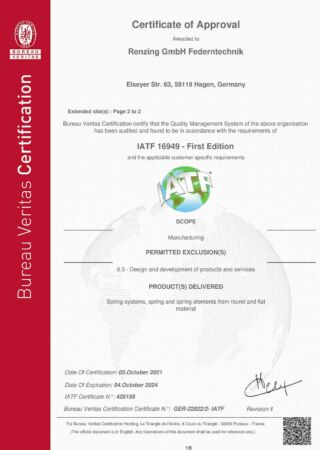

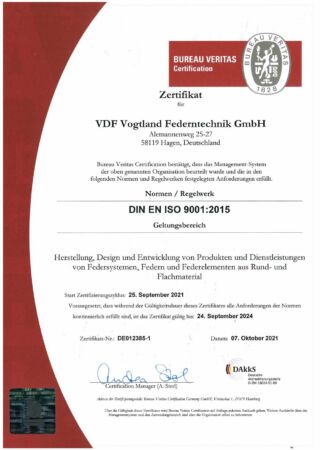

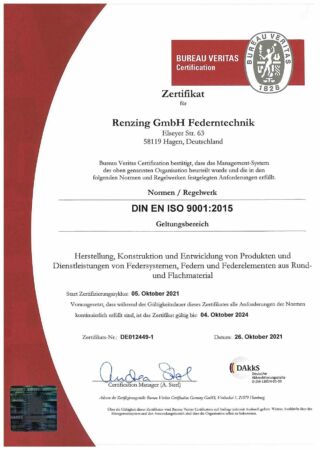

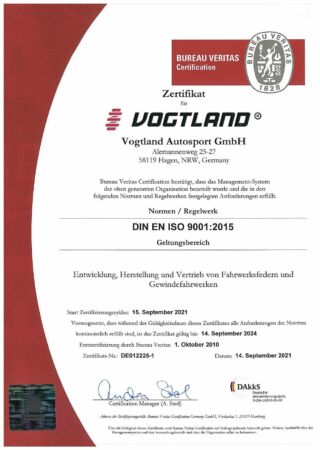

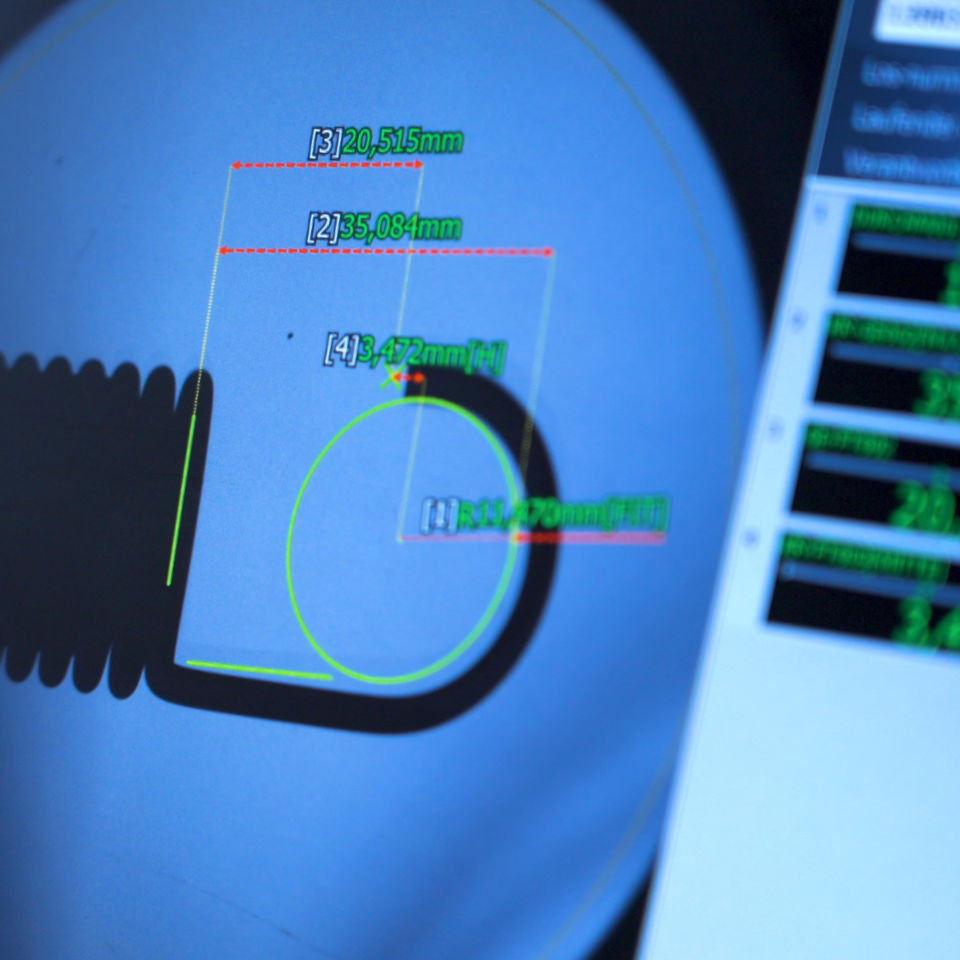

The quality management system of the VDF FEDERN Group is certified according to the international standard of the automotive industry, IATF 16949, in addition to the standard DIN EN ISO 9001:2015. Our customers set the high standards for our product quality. Quality thus means: Compliance with customer requirements in terms of function, price, advice and service, delivery time, safety, reliability, environmental compatibility, costs, as well as a courteous, friendly manner. This applies to all areas of the company.

SUSTAINABILITY

PASSION FORMS PERFORMANCE

CORPORATE

MISSION STATEMENT

PASSION FORMS PERFORMANCE

We, the VDF FEDERN group of companies, are specialists in the field of suspension technology, stamping and bending technology and chassis technology. In this area of forming technology, we focus our strengths in technically and qualitatively demanding market segments. The solution of technically difficult tasks and of special customer requirements are VDF FEDERN main focuses.

We are a complete supplier of all types of technical springs and stamped-bent parts to serve the customer as a competent partner for his needs. We see ourselves as a service provider by offering our customers complete solutions. This ranges from the assembly of subassemblies including the procurement of parts to innovative packaging solutions and logistics concepts. We strive for a leading position of the company in terms of market position, quality and service. Guidelines for building and defending our strong market position are:

- Consistent customer orientation of all employees

- Continuous improvement of our processes and products

- Creation of cost advantages to ensure international competitiveness

- Pursuit of the zero-defect strategy

- Strategic use and management of partnerships in the value chain

- Recognition and implementation of market needs and technical changes

- Focus on growing and profitable market niches

With high-tech products and with all the advantages of a medium-sized family business, we meet the requirements of our customers and especially of the automotive supply industry.

CERTIFICATES

COMPANY CHRONIC

2021

2017

2016

2011

2009

2008

2005

2001

1998

1994–1995

1992–1993

1989–1991

1974–1986

1966

1961

1958

1934

1923

1908–1923

COMPANY CHRONIC

Relocation of the punching-bending center of the RENZING company to the Lüdenscheid site and integration into the KREUTZER Stanz-Biegetechnik company. This area is expanded to the competence center for flat material including and tool making.

Acquisition of the punching and bending specialist KREUTZER GmbH & Co. KG with 85 employees. the strategic expansion into a full-range supplier is consolidated with this acquisition.

Expansion of the Elseyer Straße site. The construction of a new production and storage hall next to our Elseyer Straße site in Hagen will enable us to significantly improve our site structure.

10 years after the foundation of the American subsidiary, VOGTLAND North America successfully supplies the American aftermarket and equips well-known tuners and vehicle tuners with high-quality suspension products.

Acquisition of the technical springs division of INTEC. Establishment of a production site in Baden Württemberg and expansion of our product variety and market presence. The Hockenheim Reilingen plant specializes mainly in torsion springs, bent parts and spring rings. In addition, customers in the region are supplied directly from there.

100 years of tradition, innovation, passion, driving pleasure and Made in Germany. Today, the product range includes: compression springs, axle springs, tension springs, torsion springs, bent parts, stamped parts, assemblies and components as well as lowering springs, sports suspensions and coilovers. The VDF FEDERN brand stands for the expansive group of companies across the board.

Takeover of the spring factory RENZING GmbH with 50 employees. The VOGTLAND group of companies continues to grow with four modern equipped locations.

With the foundation of VOGTLAND North America Inc., Vogtland opens a sales and logistics office in the USA. Vogtland enters the motorsports market and becomes a key supplier to NASCAR teams.

On the occasion of the 90th anniversary of the company, the spring factory Paul Schmiedeknecht Federn GmbH & Co. KG in Hagen is taken over and continued at its previous location. The extension of the production hall at the second location Plant 2 is completed in October.

Realignment and growth. With the foundation of the subsidiary VOGTLAND Agropruziny spol. S.r.o., the complete spring tine production for the agricultural aftermarket is transferred to the Czech Republic. In November, the small spring factory Engelbrecht & Roos, Wuppertal, is taken over. Martin Vogtland (25 years old) joins the company on January 1 to become another Managing Director two years later.

Paul-Bernd Vogtland (27 years old) joins the company on October 1 and becomes Managing Director of the company on January 1, 1993. In this year, Christoph Vogtland, the partner responsible for the Chassis Technology division, passes away on May 6, and shortly afterwards on June 13, Paul Vogtland, jun.

In December 1989 the company is transformed into VOGTLAND GmbH and the name Riepelmeier, 55 years after his retirement, is taken out of the company name. Mr. Christoph Vogtland (21 years) joins the company on February 1, 1991 and pushes the start of the own brand VOGTLAND for suspension springs and sport suspensions in the passenger car aftermarket. In the 4th construction phase, a high-bay warehouse is built on Alemannenweg.

In several construction phases, the production halls on Alemannenweg are expanded and further warehouses and production halls are built on Gotenweg.

1966 to 1993 - the solid expansion of the company. At the age of 23, Paul Vogtland Jr. joins the company and takes over sole management from 1966. After 33 years, Paul Vogtland jun. expands the plant to a new location. The 1st construction phase at Alemannenweg, today's headquarters, is built. On the occasion of the 60th anniversary of the company, the new hall is occupied.

The plant was developed into an important industrial enterprise in the spring industry at that time.

On the occasion of the company's 50th anniversary, a new, modern administration building is occupied and the production facilities are again expanded. With 130 employees, a capacity of 1 million springs per day is reached. Special alloys such as chrome vanadium steel are already being processed.

11 years after the first major expansion, the company is relocated again to the Hohenlimburg-Elsey district. The sole owner Paul Vogtland sen. pushes the export quota for special springs to 35%. After 1945, in addition to mechanical engineering, the agricultural machinery industry and mining are now the main customers for Vogtland Spezialfedern.

1923 to 1965 - the expansion to an industrial company by Paul Vogtland sen. 15 years later the circle of shareholders is expanded and the company Vereinigte Draht- und Federnwerke Vogtland & Riepelmeier is founded in the new building Im Weinhof. The brand abbreviation VDF is created and mechanical engineering becomes an important customer sector.

1908 to 1923 - the founding years of Bernhard Vogtland. Master locksmith Bernhard Vogtland founds the company at the age of 40 on June 3 in a garage in Hohenlimburg, Hagen in NRW. Springs are manufactured for the toy industry and for riding and driving harnesses.