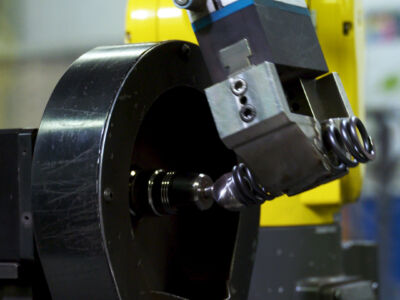

COMPRESSION SPRINGS

Compression springs in a wide variety of designs - from precision springs with 0.2 mm wire thickness to processing material thicknesses with 18 mm wire diameter.

- Mechanical and computer controlled wind machines

- Economical production, excellent product quality

- 100 percent testing of various parameters possible

- Quality inspection via network-linked CAQ system

- Mobile continuous furnaces + connection to further processing = reduction of material handling

- State-of-the-art feeding systems for economical series production of several million springs per year

- Use of computer controlled spring coiling machines

- Flexible batch sizes from small batches to large series on interlinked production lines

- High degree of automation - spring coiling, grinding, shot peening, stress relieving, plasticizing - right through to the customer's container ready for shipment

- Production of highly stressed precision springs at competitive conditions thanks to state-of-the-art technology

Highly developed applications of our customers are the mirror of our quality claim. Depending on the project, camera-supported testing equipment and fully automated testing machines are used, so our products meet the greatest requirements every day - at all times and at the highest quality level.