OUR

PRODUCTS

PASSION FORMS PERFORMANCE

With more than 400 million individually produced parts per year, we are your innovative partner for all aspects of forming technology. Customer-oriented, sustainable and with perfection. Our comprehensive product range holds an extreme competitive advantage. For you and for us. In addition, we offer you a wide variety of customer-specific solutions including assemblies in a wide range of material qualities, spring shapes, spring geometries, stress levels and surfaces.

OUR PRODUCTS

BUILDING GROUPS

STAMPED-BENT PARTS

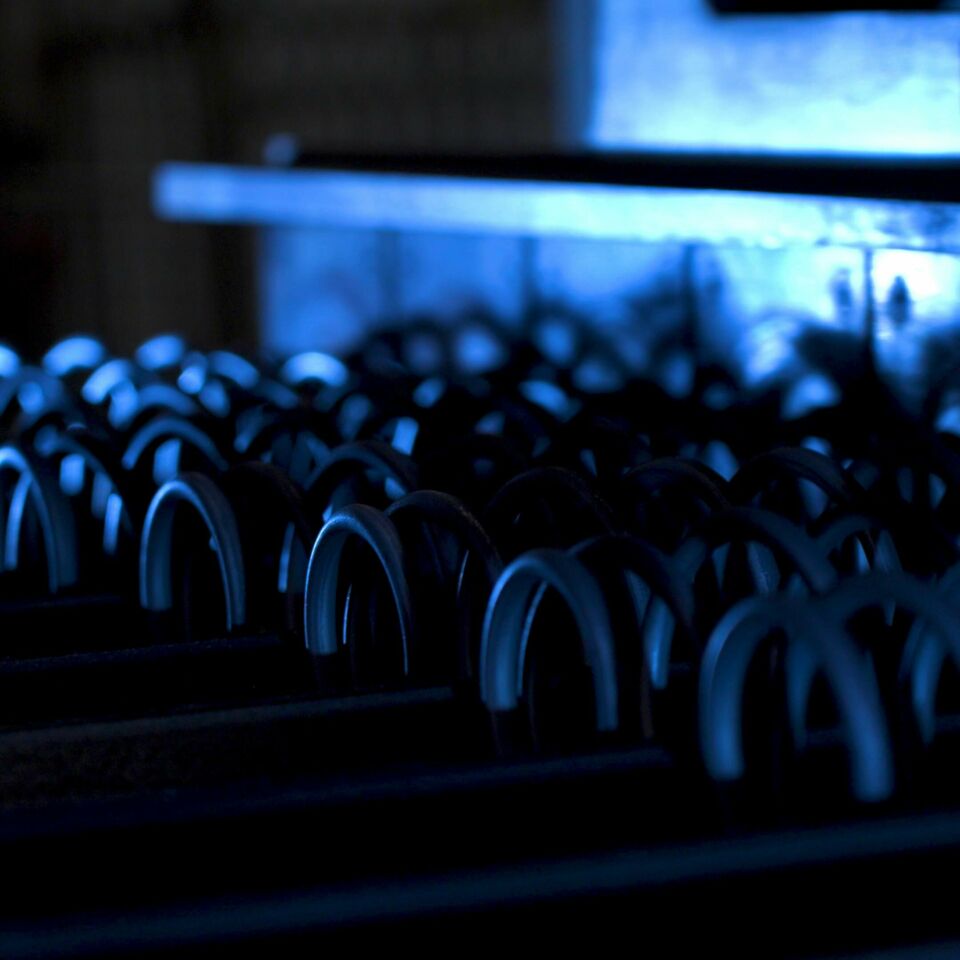

LEG SPRINGS & WIRE BENDING PARTS

TENSION SPRINGS

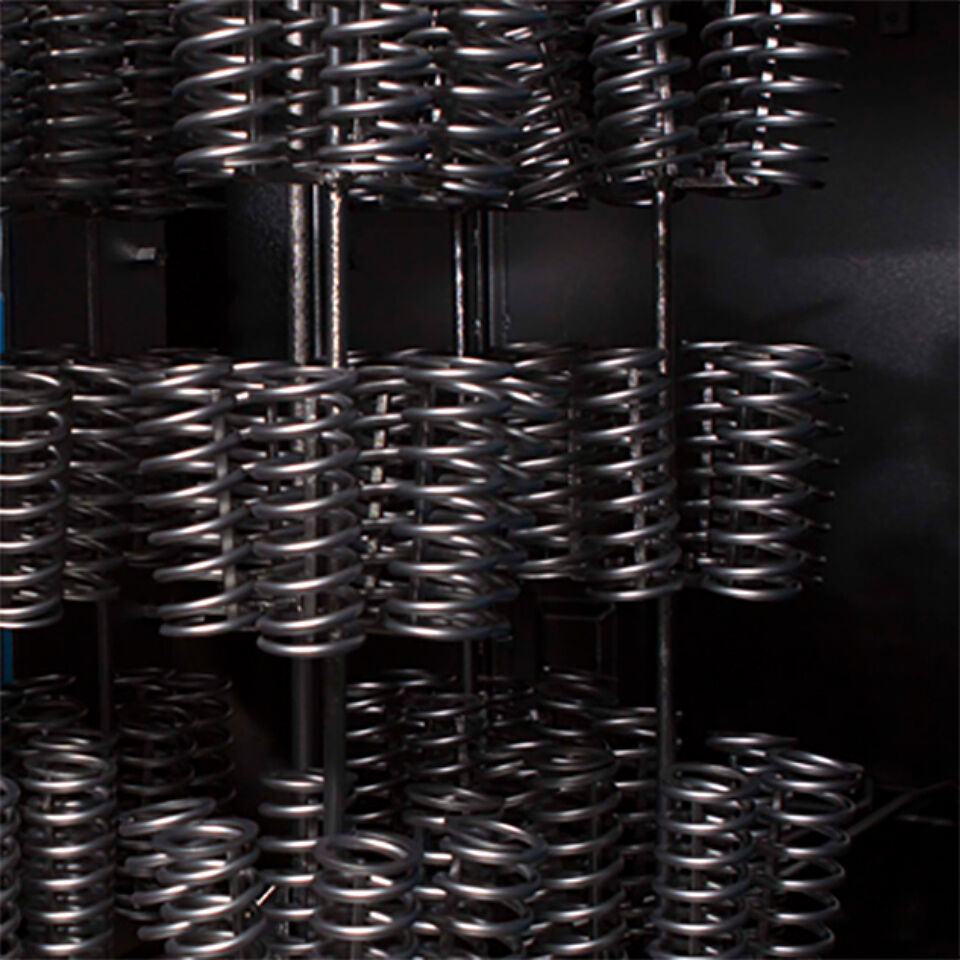

COMPRESSION SPRINGS

AXLE SPRINGS

BUSINESS SEGMENTS

AUTOMOTIVE

LEARN MOREMACHINERY AND PLANT ENGINEERING

LEARN MOREAGRICULTURAL MACHINERY

LEARN MORECONSTRUCTION AND HARDWARE INDUSTRY

LEARN MOREHOUSEWARES INDUSTRY

LEARN MOREPRODUCTION PROCESS

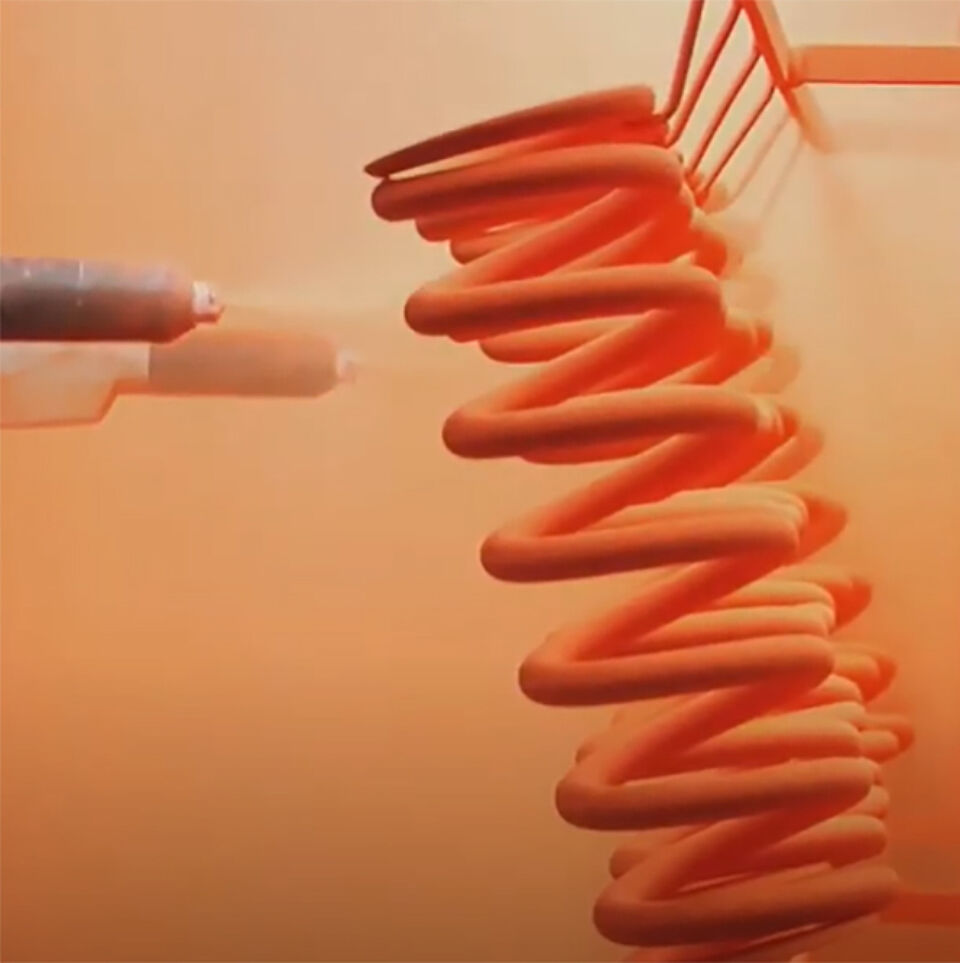

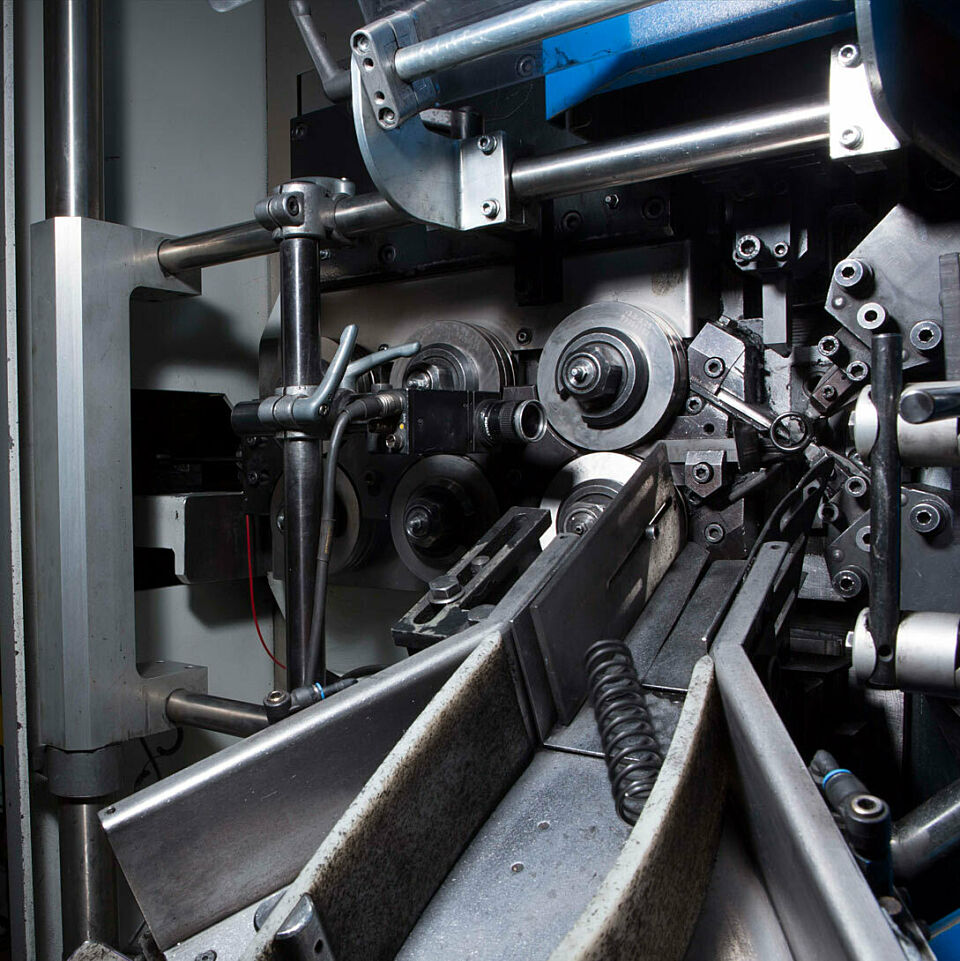

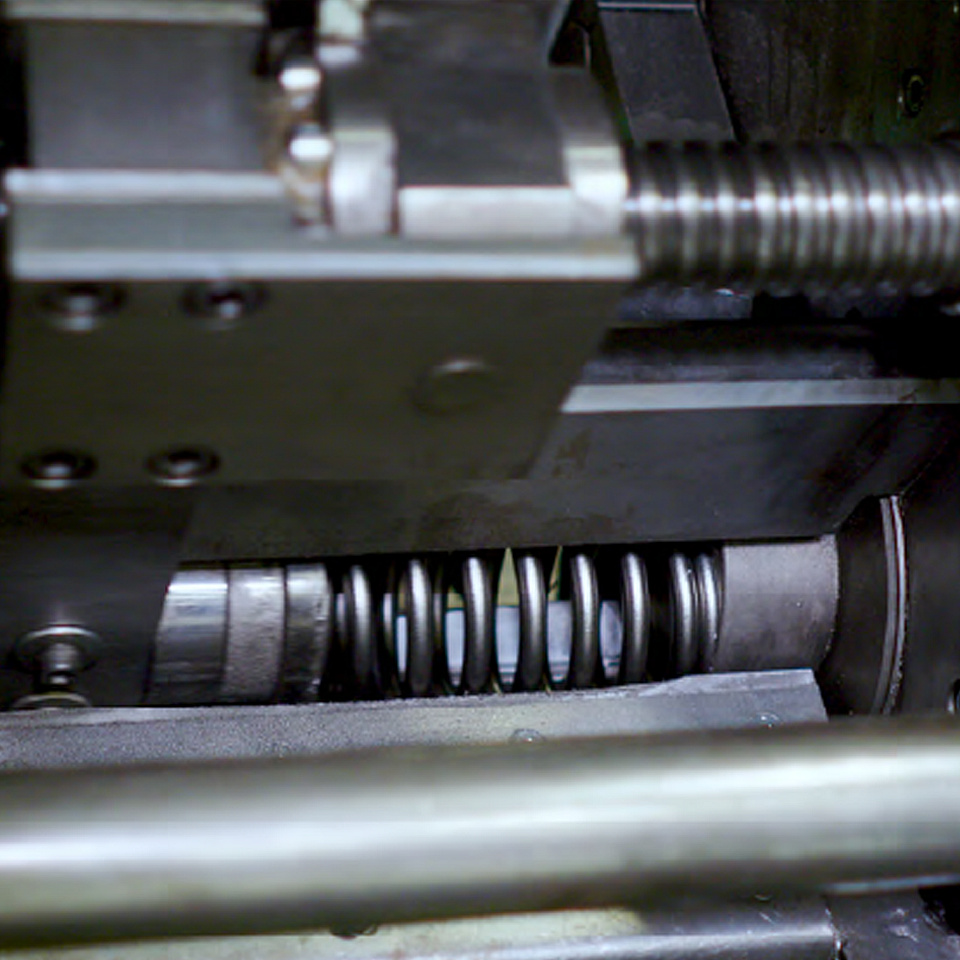

1Cold forming

The geometry of the coil spring is achieved in the first step in a non-cutting cold forming of the spring wire by a coiling or winding process. Torsion springs are usually produced by a coiling process in which the spring wire is wound around a mandrel. Compression and extension springs are formed into the desired shape by a coiling process. The figure on the right illustrates the principle of the cold coiling process. The spring-hard material is pushed into the coiling pins by means of the feed rollers, with the setting and position of the coiling pins determining the outside diameter of the spring produced. The wire is then pushed out of the coiling center by means of the pitch pin or pitch wedge. The variable positioning of the coiling pins and the pitch pin allows a wide variety of spring geometries to be produced. Finally, the wire is cut by the cutting blade, which is moved by various methods. With the help of a rotary cut, almost burr-free spring ends can be realized. We have more than 50 of the most modern cold forming coiling machines in a wire size range from 0.3 mm to 16 mm.

PRODUCTION PROCESS

2Heat treatment

The residual stresses caused by the plastic deformation of the spring-hard material are relieved by a heat treatment process called tempering. Different tempering furnaces are available depending on the spring geometry and output quantity. Continuous temperature recording ensures high product quality.

PRODUCTION PROCESS

3Spring end grinding

The design of the end coils is very important for helical compression springs. The application of the end coils and the subsequent surface grinding allow for the most axial deflection possible during force application. VDF-Federn has more than 25 state-of-the-art CNC-controlled spring end grinding machines. Thanks to the effective cooling of the grinding process and the enormous extraction capacities of the filter systems, optimum product quality is achieved. Numerous grinding machines are also equipped with fully automatic feeding devices.

PRODUCTION PROCESS

4Shot peening

For many demanding customer applications, the fatigue strength of the spring used is enormously important. Shot peening can significantly increase the fatigue strength of the spring. By means of shot peening wheels, rounded wire grit of defined hardness and size is thrown onto the springs at high speed. The resulting compressive stresses and strain hardening in the surface layers of the spring material lead to an increase in fatigue strength. The smoothing of the surface also mitigates the effects of surface defects. Several troughed belt shot blast machines and overhead belt shot blast machines are available for the various products and applications.

PRODUCTION PROCESS

5Plasticize

Plasticizing of springs, also called setting or pre-setting, is used to achieve both greater material utilization and optimization of the spring properties. The residual stresses generated during overelastic loading of the spring reduce the subsequent load stress in the spring insert. This additional operation prevents subsequent loss of length (setting loss) of the spring in the insert and increases the load capacity of the spring. Different cold and hot setting devices are available for the various applications of our customers. Here, too, the use of automatic feeders ensures efficient production.

PRODUCTION PROCESS

6Surface processing

Many of the spring steel wires we use already offer corrosion protection. In addition, numerous surface coating processes are available, such as epoxy, polyester, KTL, Dacromet, delta coatings and galvanic treatments.